Wire rope tester for naval facilities and offshore

The use of large diameter wire ropes, particularly in the naval sector and offshore, has brought AMC to expand the ROPE range with suitable detector: ROPEX130 and ROPEX165.

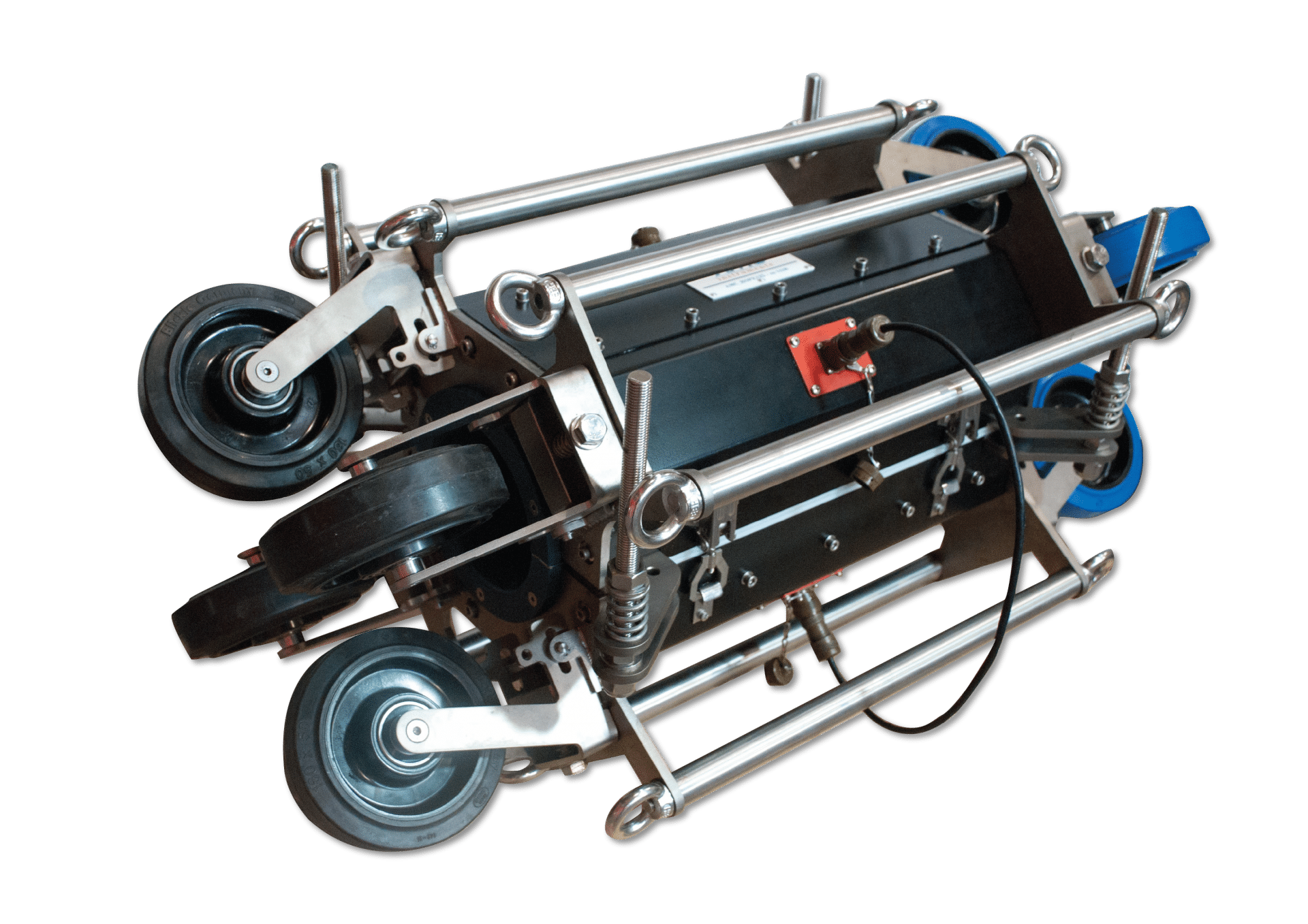

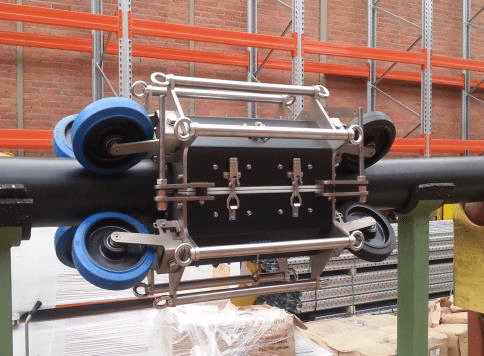

The detectors are equipped with a 8 wheels centering system properly designed to minimize the oscillation and therefore the signal noise.

The ROPEX system helps the people involved in the maintenance or test of ropes, to highlight localized fault, internal and external broken wires or cross section reduction (e.g. corrosion or abrasion) in a simple, quick and efficient way in accordance with standard UNI ISO 4309.

This wire rope tester, which performs a magneto-inductive test, is wire connected to an acquisition unit (IASH) that displays real-time signalsand store the data in order to create the test report.

As the metal section to be checked is large, AMC has developed an innovative multichannel sensor to provide information on the position and depth of the defect. ROPEX range for large diameters is certified according to ASTM1571.

Device features:

ROPEX130 Weight: 150kg; ROPEX165 Weight: 200kg;

Max n° ropes: 1;

Controlled diameters: from 90 mm to 160mm

Magnetic field source: Permanent magnets (NdFeB)

Sensor type: multi Colis

Measured signal: 5 LF channels

Acquisition system: IASH

IASH battery autonomy in continuous operation: 24 hours

Operating temperature: -20C° / +50C°

Performance:

Defect resolution: 0,5%